The 24 Pounder Cannon

Description

![]() Introduction

Introduction

![]() Parts of the Cannon

Parts of the Cannon

![]() Traversing Platform

Traversing Platform

![]() Specification of the Cannon

Specification of the Cannon

![]() Gunpowder Charge

Gunpowder Charge

![]() Markings on the Cannon

Markings on the Cannon

![]() Ammunition

Ammunition

![]() Gunpower

Gunpower

![]() Cannon Flintlocks

Cannon Flintlocks

![]() Firing the Cannon

Firing the Cannon

![]() Samuel Walker & Co

Samuel Walker & Co

![]() Photo Gallery

Photo Gallery

![]() Video Explaining the Different KInds of Shot During the Napoleonic Wars

Video Explaining the Different KInds of Shot During the Napoleonic Wars

![]() Video of the Firing of a 24 Pounder Cannon

Video of the Firing of a 24 Pounder Cannon

![]() 'The Interior of a Cannon Foundry' by JMW Turner

'The Interior of a Cannon Foundry' by JMW Turner

(where most of the photos on this page were taken)

The main armament of a Martello Tower was normally a 24 pounder smooth-bore muzzle-loading gun mounted on a carriage capable of traversing 360 degrees. A few towers had 32 pounder cannons.

The cannon is characterized by a longer barrel, larger propelling charges, smaller shells, higher velocities, and flatter trajectories. The 24 pounder/32 pounder cannon on the gun platform of a Martello Tower was a typical cannon of the time, used both by the Army and on the Royal Naval ships.

The cannon was muzzle loading, weighed about 2.5 tons and had a range of about a mile at 5 degrees elevation. Its main charges were a solid shot, canister shot or case shot, grapeshot or shrapnel (find out more below). The cannon was mounted on a traversing platform on wheels that ran along rails. This allowed the gun to be traversed (turned) very quickly to bear on a moving enemy. The recoil from firing forced the gun backwards up the sloping rails for reloading. It could then be 'run out' again for firing again. (find out more below)

24 Pounder cannon on the parapet of Martello Tower No.24 in Kent, UK

Firing solid shot, the 24-pounder guns could have caused immense damage to lightly-built invasion craft as they neared the shore. If the invasion forces reached the beaches, such heavy shot was even more lethal to dense masses of troops - there are records from battles elsewhere of up to 40 men being killed by a single shot at a range of 600-800 yd (549-732 m).

To kill enemy troops within about 350 yds (320m) range, the Martello gunners would have started to fire case-shot, which could be either `heavy' or `light'. The former consisted of 84 6oz balls contained in a thin metal canister, the latter of 232 2oz balls similarly packed. When fired, the canisters burst, spraying a deadly hail of bullets.

A single round of heavy case-shot was almost as lethal as a volley of musket-shot from an infantry company of 100 men and an efficient gun's crew would be expected to maintain a firing-rate of three canisters a minute, although perhaps for only a comparatively short time. Given such opposition, even the pick of Napoleon's troops might have faltered.

The Cinque Ports Volunteers who helped man the Martello Towers in Kent, UK

Side elevation of a typical 19th-century cannon

- Bore: The hollow cylinder bored down the centre of the cannon, including the base of the bore or bottom of the bore, the nearest end of the bore into which the ordnance (wadding, shot, etc.) gets packed. The diameter of the bore represents the cannon's calibre.

- Chamber: The cylindrical, conical, or spherical recess at the nearest end of the bottom of the bore into which the gunpowder is packed.

- Vent: A thin tube on the near end of the cannon connecting the explosive charge inside with an ignition source outside and often filled with a length of fuse; always located near the breech. Sometimes called the fuse hole or the touch hole. On the top of the vent on the outside of the cannon is a flat circular space called the vent field where the charge is lit. If the cannon is bronze, it will often have a vent piece made of copper screwed into the length of the vent.

The main body of a cannon consists of three basic extensions: the foremost and the longest is called the chase, the middle portion is the reinforce, and the closest and briefest portion is the cascabel or cascabel.

The chase: Simply the entire conical part of the cannon in front of the reinforce. It is the longest portion of the cannon, and includes the following elements:

- The neck: the narrowest part of the chase, always located near the foremost end of the piece.

- The muzzle: the portion of the chase forward of the neck. It includes the following:

- The swell of the muzzle refers to the slight swell in the diameter of the piece at the very end of the chase. It is often chamfered on the inside to make loading the cannon easier. In some guns, this element is replaced with a wide ring and is called a muzzle band.

- The face is the flat vertical plane at the foremost edge of the muzzle (and of the entire piece).

- The muzzle mouldings are the tiered rings which connect the face with the rest of the muzzle, the first of which is called the lip and the second the fillet

- The muzzle astragal and fillets are a series of three narrow rings running around the outside of the chase just behind the neck. Sometimes also collectively called the chase ring.

- The chase astragal and fillets: these are a second series of such rings located at the near end of the chase.

- The chase girdle: this is the brief length of the chase between the chase astragal and fillets and the reinforce.

The Cinque Ports Volunteers 'firing' the 24 Pounder Cannon

The reinforce: This portion of the piece is frequently divided into a first reinforce and a second reinforce, but in any case is marked as separate from the chase by the presence of a narrow circular reinforce ring or band at its foremost end. The span of the reinforce also includes the following:

- The trunnions are located at the foremost end of the reinforce just behind the reinforce ring. They consist of two cylinders perpendicular to the bore and below it which are used to mount the cannon on its carriage.

- The rimbases are short broad rings located at the union of the trunnions and the cannon which provide support to the carriage attachment.

- The reinforce band is only present if the cannon has two reinforces, and it divides the first reinforce from the second.

- The breech refers to the mass of solid metal behind the bottom of the bore extending to the base of the breech and including the base ring; it also generally refers to the end of the cannon opposite the muzzle, i.e., the location where the explosion of the gunpowder begins as opposed to the opening through which the pressurized gas escapes.

- The base ring forms a ring at the widest part of the entire cannon at the nearest end of the reinforce just before the cascabel.

The cascabel: This is that portion of the cannon behind the reinforce(s) and behind the base ring. It includes the following:

- The knob which is the small spherical terminus of the piece;

- The neck, a short, narrow piece of metal holding out the knob; and

- The fillet, the tiered disk connecting the neck of the cascabel to the base of the breech.

- The base of the breech is the metal disk that forms the most forward part of the cascabel and rests against the breech itself, right next to the base ring.

The cannon was mounted on a variation of the garrison wooden carriage which itself was mounted on a traversing platform. The platform had an incline which helped reduced the recoil of the cannon when it was fired.

The traversing platform on which the gun was mounted consisted of two roughly squared timber beam of tìmber each 1ft (4.9m) long held together by three crosspieces, with a pair of small iron wheels fitted under the front crosspiece, and with a second pair at the rear on two legs, which raised the platform to an angle of about 20 degrees.

The front wheels ran on a metal track, or racer, laid along a narrow stone ledge built at the base of the parapet wall, while the rear wheels ran along a similar track, but one with a much narrower diameter, which encircled a metal pivot and was mounted on a circular masonry block.

24 Pounder Cannon on the parapet of Martello Tower No.24

A 24 pounder cannon mounted on a traversing platform required an interior space of about 20ft (6.15m) in diameter within the parapet to be able to traverse freely in all directions. The pivot was frequently just an iron spike secured in the muzzle of an old, unserviceable gun barrel which was embedded upright in the centre of the gun platform.

This use of a gun barrel was an

economical way of ensuring that the pivot could be raised to a height which gave the traversing platform an incline from front to the rear of between 10 and 20 degrees and was also strong enough to support both the weight of the platform and the gun.

The traversing platform and hence the cannon was moved by using blocks and tackles and ropes through metal rings fixed to the inside wall of the parapet, and on the UK south-coast towers the platform could be turned quite easily through 360 degrees.

Cannon on its traversing its carriage and traversing platform

It was officially known as the 24 Pounder Smooth Bore Iron Long Cannon and, in 1805/6, was cast to the pattern designed by Major General Sir Thomas Blomfield, who was appointed Inspector of Artillery at the Royal Brass Foundry of Woolwich in 1780.

Length 10 feet

Weight 52 cwt.

Calibre 5.823 inch

Charge Weight 8 lbs

Projectile Weight 23.5 lbs

Muzzle Velocity 1720 ft. sec.

Muzzle Energy 482 ft. ton

Range (effective) 1000 yards

Saltpetre 75% = Potassium Nitrate

Charcoal 15% = Dogwood, Alder or Willow

Sulphur 10%

Standard colour = Slate Black

The photos on the right are of the 24 pounder cannon on the parapet of Martello Tower No.24 in Dymchurch, Kent, UK and was manufactured by Samuel Walker & Co in Rotherham. The company was one of the largest cannon manufactures in the UK. About 80 of the 105 guns aboard HMS Victory at the Battle of Trafalgar were cast by the Walker Company.

Cannons manufactured in the UK by Samuel Walker & Co are easy to identify providing they still retain the special marks placed on them during the casting process.

- On the end face of the left Trunnion (looking in the direction of fire) will be found the mark ‘WCo’ which stands for Walker & Company.

- On top of the barrel and just behind what is called the second reinforce will be found the Royal Cypher of George III who died in 1820. This was the same year in which production came to an end at Rotherham so any Walker cannon found with a George IV cypher will have been produced at the Gospel Oaks Works, Tipton, Staffordshire.

- Other marks to be found are the casting number on the end face of the right Trunnion and the weight of the ones (the old Imperial Measure) on the lower part of the breech end (cascabel) of the barrel.

- There will also be found a broad Government arrow stamp and markings on the barrel, the latter being used by the gunners for the purpose of ranging the gun onto its target.

Photos of the original 24 Pounder Cannon still installed on Martello Tower No.24 in Dymchurch, UK

Photo A: Touch hole and raised mount for a flintlock

Photo B: Markings used ranging the gun onto its target

Photo C: Royal Cypher of George III

Photo D: Casting number on the end face of the right Trunnion,

Photo E: Mark ‘WCo’ (Walker & Company) on the end face of the left Trunnion

![]() more photos of Martello24

more photos of Martello24

Round Shot

A round shot is a solid spherical iron projectile without explosive charge launched from a gun/cannon. Its diameter is slightly less than the bore of the barrel from which it is shot.

A round shot fired from a large-caliber gun is also called a cannonball.

24 pound Cannonballs

Cannister/Case/Grape Shot

Canister/Case shot consists of a closed metal cylinder typically loosely filled with round lead or iron balls packed with sawdust to add more solidity and cohesion to the mass and to prevent the balls from crowding each other when the round was fired.

A variation of the cannister/case shot was grapeshot but with the shot being contained in a canvas bag,

Cannister Shot

Gunpowder, also known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical explosive. It consists of a mixture of sulphur, charcoal and potassium nitrate. Because of its incendiary properties and the amount of heat and gas volume that it generates, gunpowder has been widely used as a propellant in firearms, artillery, rockets, and fireworks, and as a blasting powder in quarrying, mining, and road building.

Gunpowder was invented in 9th-century China and spread throughout most parts of Eurasia by the end of the 13th century. Originally developed by the Taoists for medicinal purposes, gunpowder was first used for warfare in about 904 AD.

Ignition of gunpowder packed behind a projectile generates enough pressure to force the shot from the muzzle at high speed, but usually not enough force to rupture the gun barrel. Gunpowder thus makes a good propellant but is less suitable for shattering rock or fortifications with its low-yield explosive power.

![]() Reference and more information

Reference and more information

Black powder for muzzleloading firearms

and in FFFg granulation size.

Coin (diameter 24 mm) for comparison

Gunpowder store in Martello Tower No.24

Prior to cannon ignition ‘locks’ being used, typical firing of cannon would be with a quill primer or open powder train which was touched off with either a handheld linstock or portfire. Use of either of these methods required the gunner to be in close proximity to the cannon’s vent and left the artillerist subject to possibly be in line of the cannons’ recoil, or in the event of the failure of the tube; undoubtedly in harm's way.

Cannon locks were developed and put into use first probably by the British in the mid-1700s. They were quickly viewed as an improvement over the earlier systems used. The gunner would use a rope and lanyard to fire the cannon now which allowed him to be further away from the cannon on ignition. Also, in the case of a naval gun, the ignition was speedier which allowed for better shooting accuracy on moving ships and rolling seas.

The brass body consists of two pieces with the release spring and cocking mechanism inside, as typical with a flintlock gun. At the rear of the lock, is an iron piece which has a hole in it for the lanyard line to attach. Black powder was filled into the pan and the frizzen closed to protect the powder from the wind and elements. The hammer which held a flint was pulled back or cocked readying the piece. A quick pull on the outstretched lanyard released the hammer and the flint would strike the steel frizzen hopefully creating a spark which would instantaneously light the powder in the pan and set off the propellant charge.

Cannon Flintlock c1790

Cannon locks would either mount onto a raised cast section (see right) on the barrel next to the vent, or onto an applied mount next to the vent. On some older cannon barrels, you can see the cast on mounts, or the threaded holes for screws used for attaching the mount next to the vent. (see pictures right of the raised cast section on the Martello24 cannon)

Besides different manufacturers and countries of origin, some have different stampings such as anchors and other inspectors marks. Some are numbered so if they are removed from a certain cannon, they could be matched back when needed.

Cannon locks are very rare to find today. Eventually, flintlock style cannon locks were replaced with a percussion style system of ignition which was a further improvement. After the simpler friction primer was introduced, cannon locks fell into disuse.

Extract from https://issuu.com/artillerymanmagazine/docs/fall_2015/4

Raised section cannon for flintlock

It took upwards of 11 men to both manoeuvre and fire the cannon. Every man in the gun crew was assigned specific tasks with a senior soldier known as the Gun Captain in charge. He was responsible for seeing that every man did his work, delivering a safely loaded cannon for him to prime, sight and fire.

One man loaded the cartridge into the gun, followed by a cloth wad (typically made from canvas and old rope), whilst another rammed it home with a flexible or wooden rammer. The gun captain would feel for and pierce the flannel cartridge with a small length of wire, known as a pricker, placed down the touch-hole in the breech of the gun, shouting 'Home!' when he had made contact. On the command 'Shot your guns!' a round shot was loaded into the barrel followed by another wad (to prevent the cannonball from rolling out of the barrel if the muzzle was depressed) and rammed home.

The gun was then 'run out' by hauling it along its traversing platform up to the parapet using gun tackles until the front of the gun carriage was forward as far as it could go, with the barrel protruding just beyond the top of of the inside of the parapet. It was then trained left/right using rope tackles and elevated using crows of iron to raise the breech and then moving the quoin, a wooden wedge that lowers the barrel the further it is pushed forward.

Picture of soldiers working the cannon

The touch-hole was then primed using a mixture of fine powder and spirits of wine from a priming horn or a 'quill' (from a porcupine or such, or the skin-end of a feather) pre-filled with priming powder. It would be fired either using a flintlock; a mechanism bearing a flint similar but heavier than that found on muskets, or a linstock, a wooden staff holding a length of smouldering slow match kept burning in a bucket when not in use. If a flintlock was being used the hammer was pulled back to half cock at this point.

The hammer was pulled back to full cock as soon as the captain was happy with his sighting, and he raised his hand signalling the gun as ready. In his other hand, he held a long lanyard or trigger line connected to the lock or the linstock.

On the command 'Fire!' the line was pulled and the hammer clicked creating a spark or the linstock was applied to the touch-hole creating a small explosion in the pan as the priming powder ignited which in turn set off the main charge propelling the shot out of the barrel. As the gun fired it was hurled violently backwards in recoil until it was stopped by the breech rope — a sturdy rope made fast to ring bolts set into the parapet, and a turn taken about the gun's cascabel, the knob at the rear end of the gun

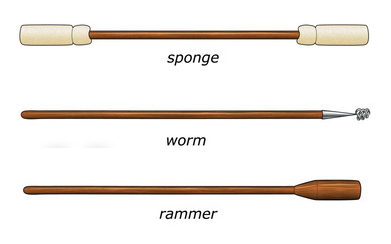

These tools were used to load and clean out the cannon

Samual Walker & Co was the largest and most successful ironworks in Rotherham in Britain in the 18th and 19th century.

It was founded in c 1741 by Samuel Walker and his younger brothers, Aaron and Jonathan. The business of quickly blossomed and was soon manufacturing “cannon of the largest calibre and almost all other cast-iron articles”, which would have far-reaching effects for the future of this Country on both land and sea. By the year 1774, an additional site was being developed for the casting of iron guns (cannon) in the form of a new casting house, two boring houses, three air furnaces, etc.

The Company, with access to both coal and iron ore in the immediate vicinity, was perfectly placed to take full advantage of the recently brewing conflict which was to become known as the American War of Independence (1775-1783). Debentures for guns in that first year amounted to just 40 tons rising to 1220 tons by 1781 and then reducing dramatically as the war came to an end. From then it would seem that a steady order for guns was received along with ever-increasing demands for improved quality due to the development of ever more powerful gun powders. Production was carried on in Rotherham up until the year 1820 when the Company moved its cannon manufacturing business to a new site in Staffordshire.

Cannon manufactured in Rotherham are very easy to identify providing they still retain the special marks placed on them during the casting process. Find out more

'The Interior of a Cannon Foundry' by JMW Turner 1797/8 courtesy of the Tate Gallery